國立高雄科技大學/機電工程系/模貝與鍛壓製程技術中心

Our team possesses exceptional capabilities in technology integration and innovative R&D, specializing in the application of artificial intelligence, production management, and metaverse technologies across various Industry 4.0 scenarios. We demonstrate strong technical advantages, particularly in smart scheduling, smart factory development, and electromechanical-IT integration. The team excels in leveraging multi-objective optimization techniques to boost production efficiency and incorporates AI algorithms to enable factory automation and intelligent management. With extensive industry experience and innovative thinking, we provide highly customized smart solutions, empowering clients to achieve energy savings, efficiency gains, and digital transformation objectives.

Digital Supply Chain Integration and AI Application for the Manufacturing Industry

Solution Description

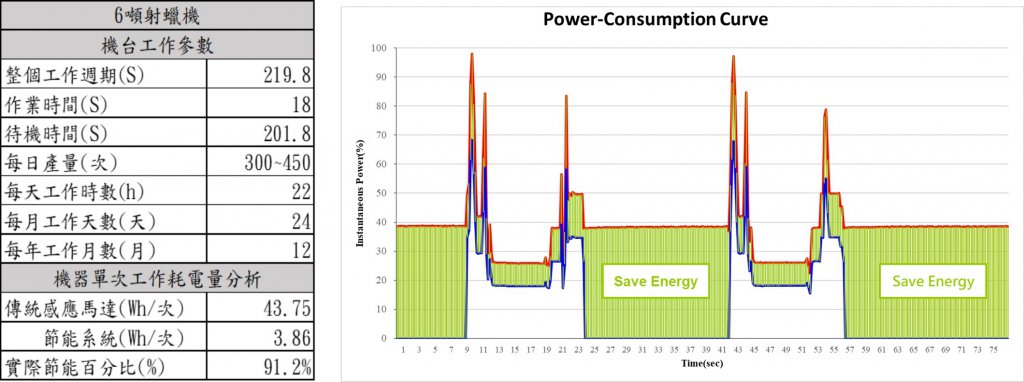

This solution integrates digital supply chain streaming and AI-driven scheduling to build an efficient and transparent production system. Core technologies include AI scheduling, digital twins, smart warehousing, and energy management, ensuring real-time data flow, precise decision-making, and improved production stability.

Expected outcomes include a 20% increase in production efficiency, a 20% reduction in machine idle time, a 10% improvement in order fulfillment accuracy, and 10% shorter lead times. By implementing smart warehousing, inventory stagnation is reduced, material flow is optimized, and businesses gain a competitive edge in digital transformation and sustainability.

、Firefox

、Firefox  、Edge

、Edge  瀏覽器!

瀏覽器!